The advanced 3D AOI system TR7700Q SII is engineered to deliver maximum precision and efficiency in SMT production. Combining automatic optical measurement, AI-driven defect detection, and full Smart Factory integration, this AOI machine ensures reliable quality control for today’s automated production lines.

With ultra-high resolution and advanced 3D inspection functions, the AOI machine enables fast programming, zero false calls with reliable defect detection, and real-time communication within the SMT production line. By reducing human error and lowering operational costs, the TR7700Q SII boosts throughput while maintaining consistently high quality.

AOI System by TRI – Key Benefits at a Glance

AOI Machine TR7700Q SII – Exclusive Features

Depth from Focus Module

Generates precise 3D models, eliminates false calls, and ensures reliable and fast inspection with ultra-high resolution imaging.

Key Benefits:

- Zero false calls: Delivers reliable inspection results without false alarms.

- Exceptional Accuracy: Provides ultra-high resolution down to 0.5 µm / 1 µm.

- Optimal Focus Imaging: Creates perfectly focused 3D images for accurate defect detection.

- Shadow-Free Inspection: Ensures precise results even for components with complex shapes and challenging geometries.

- Reduced Operator Workload: Minimizes manual rechecks, saving both time and production resources.

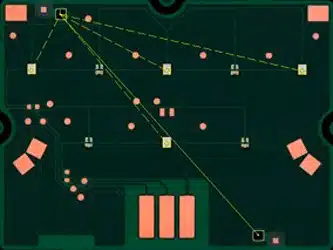

Automatic Optical Measurement Module

The AOM module delivers precise,

data-driven inspection with unique

real-time measurement capabilities. It supports components up to 40 mm in height and allows user-defined formulas and thresholds for maximum flexibility.

Key Benefits:

- Real-Time Feedback: Provides immediate results for continuous production optimization.

- High Precision: Ensures reliable and stable measurement accuracy.

- Flexible Metrology: Capture points, lines, angles, distances, and

planes – even for complex assemblies. - Advanced Multi-Layer Measurement: Enables precise inspection of components across multiple height levels.

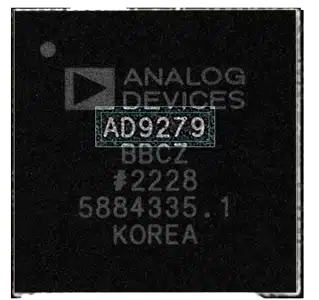

AI DLOCR - Deep Learning Optical Character Recognition

The AI-powered DLOCR function applies deep-learning algorithms to recognize even the most difficult characters, including

low-contrast, transparent, or distorted markings. It delivers significantly higher consistency and precision compared to conventional OCR methods.

Key Benefits:

- Highest Accuracy: Achieves up to 99.58% precision through advanced AI training.

- No Reference Images Required: Reduced setup time and easier integration.

- Flexible Recognition: Identifies a wide variety of fonts, formats, and orientations.

- Continuous Improvement:

Deep-learning models store character data for ongoing optimization.

Your SMT Production in Focus: Our Turnkey Solutions

Your SMT production deserves the optimal combination of efficiency, precision, and quality. Our turnkey SMT lines provide fully integrated solutions with perfectly synchronized machines and cutting-edge technologies to ensure maximum performance and process reliability.

Discover more about our complete SMT line solutions and get expert advice from our team to find the perfect setup for your production needs.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: