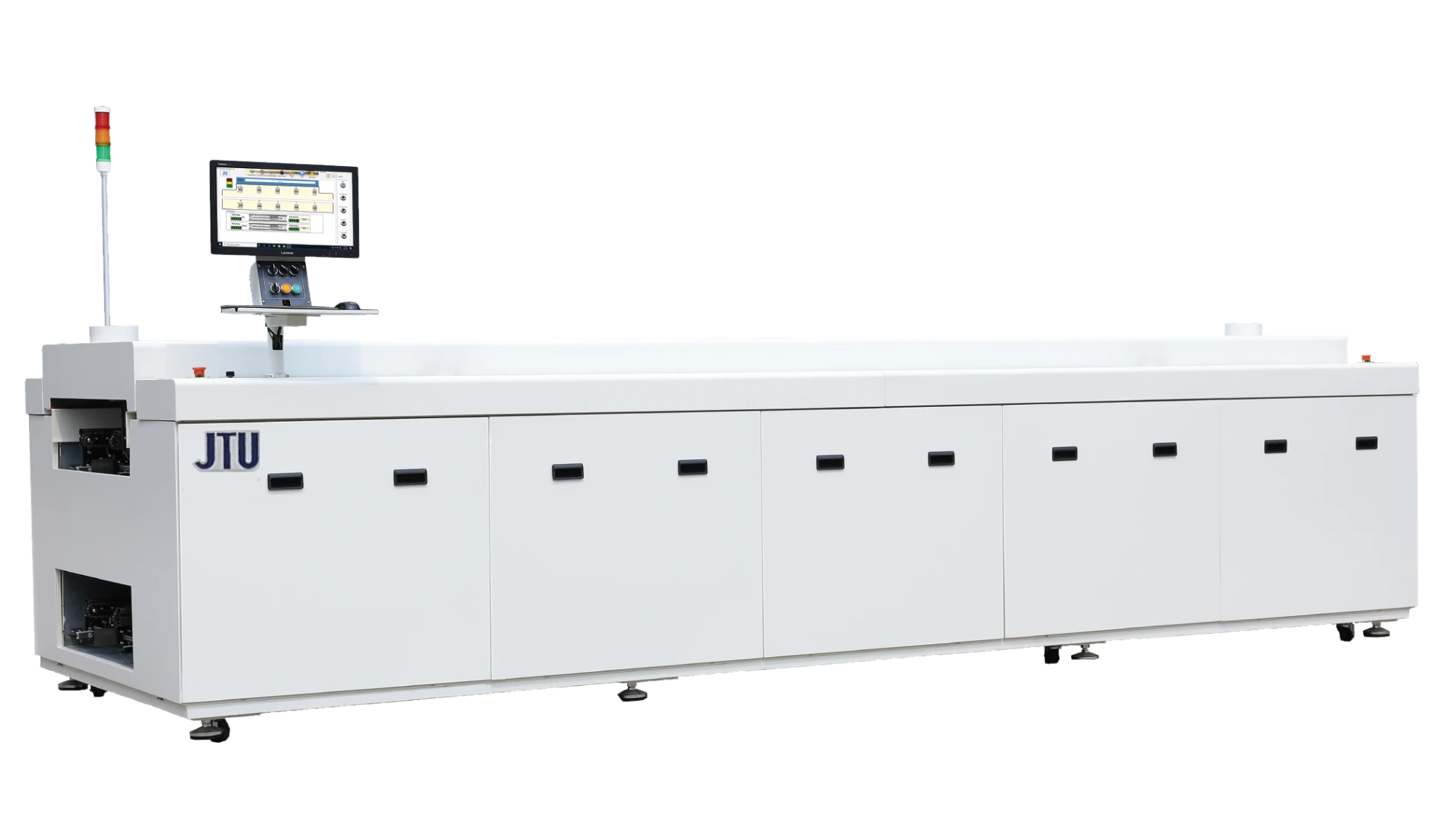

The jCURE+ Series IR Oven is the ideal solution for conformal coating processes in SMT production, setting new benchmarks in electronics manufacturing. With its modular design and advanced infrared technology, the oven ensures efficient and uniform curing of PCBAs. Its unique design optionally allows for the heating length of two ovens to be integrated into a single unit – saving both space and investment costs.

Key Features of the

jCURE+ Series IR Oven:

What is Conformal Coating?

Conformal coating is a thin protective layer applied on the surface of PCBA to shield them from environmental influences such as moisture, dust and corrosion. This coating is typically applied using an automatic selective coating machine, which ensures high precision and repeatability.

Work Process of the JCURE+ Series IR Oven

An infrared curing oven uses IR radiation to precisely apply heat to the coated surfaces of the PCBAs. This technology is ideal for drying and curing processes, as it efficiently removes moisture and helps conformal coatings achieve their intended physical and chemical properties.

Benefits of Infrared Technology:

Why the jCURE+ Series Infrared Curing Oven Is the Smarter Choice for Your Conformal Coating Line

Advantages of the jCURE+ Series IR Oven:

Optional Features:

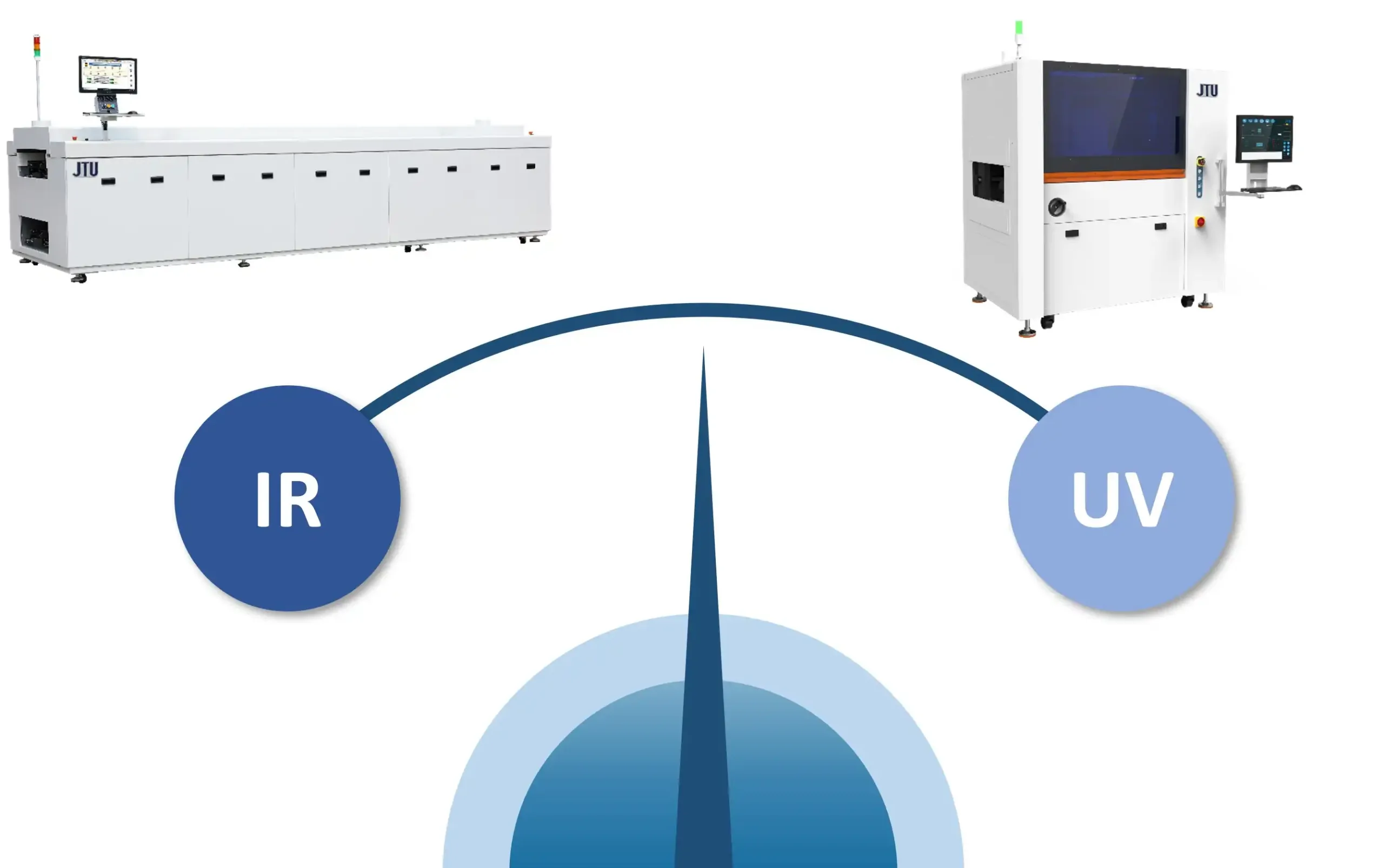

Optimized Conformal Coating: Our Complete Solution for Your Production

Your electronics manufacturing deserves the best combination of efficiency, precision and quality. Our complete conformal coating solutions provide you with a fully integrated production line that leverages state-of-the-art technologies to ensure maximum process reliability and product quality.

Discover more about our complete conformal coating solutions and let our team provide you with an individual consultation to find the ideal line solution for your production.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: