Automatic Selective Coating Machine C5 – Precise Conformal Coating for SMT Production

Automatic Selective Coating Machine C5 – Precise Conformal Coating for SMT Production

The Automatic Selective Coating Machine C5 is a state-of-the-art solution for the precise application of conformal coatings on PCBAs in SMT manufacturing. It enables highly accurate and selective coating of specific areas on the boards, avoiding material waste and improving product quality.

Equipped with three valves and a ±180° rotating head, the C5 offers exceptional flexibility, making it ideal for high-mix production and complex PCB layouts.

The machine features precise programming and advanced spray technology to ensure high-precision conformal coating. Thanks to its intelligent automated control, the system delivers outstanding results even for complex boards.

What is Conformal Coating?

Conformal coating is a thin protective layer applied on the surface of PCBA to shield them from environmental influences such as moisture, dust and corrosion. This coating is typically applied using an automatic selective coating machine, which ensures high precision and repeatability.

Advantages of the C5 Automatic Selective Coating Machine

Optimal Valve Options for the C5 Selective Coating Machine

CS-05 Atomizing Spray Valve

- High efficiency for SMT conformal coating.

- Applies a thin, uniform layer of coating.

- Coating width range: 5-10 mm.

- Suitable for low to medium viscosity fluids (1 ~ 5,000 cP).

- Ideal for high-mix production and precise coverage.

PD-01 Precision Dispensing Valve

- High precision for dotting, lines, potting, and dam creation.

- Supports needle dispensing with various diameters.

- Coating width range: 1-4 mm.

- Suitable for low to medium viscosity fluids (1 ~ 10,000 cP).

FS-30 Wide-Area Spray Valve

- High productivity for broad surface coating.

- Applies a thin layer across wide areas.

- Coating width range: 15-30 mm.

- Suitable for low to medium viscosity fluids (1 ~ 5,000 cP).

- Optimized for coating large PCBs and modules.

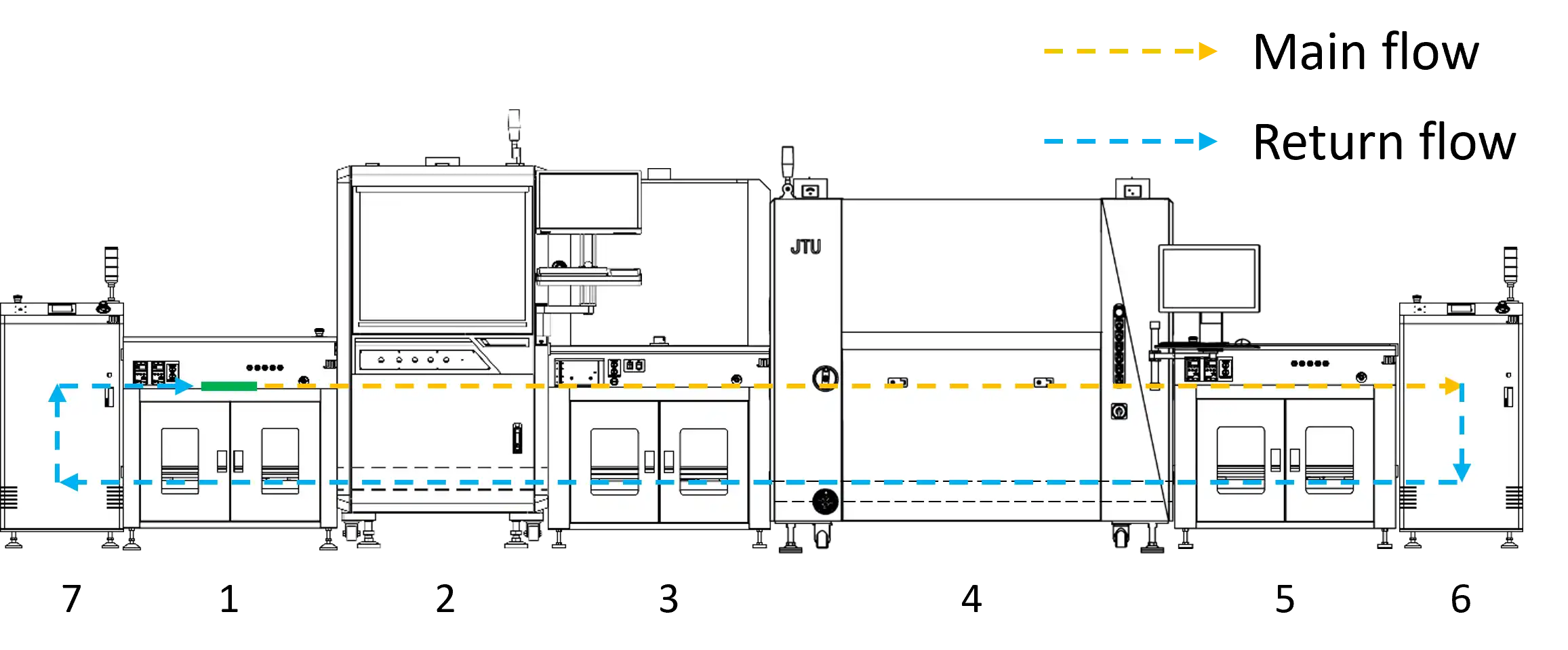

One-Man-Operator Concept: The Revolution of Coating Lines

The One-Man-Operator (OMO) concept optimizes the entire coating process by drastically reducing manual labor. With a pallet return conveyor and automated handling, the entire line can be efficiently operated by just one person. This means fewer manual interventions, more automation, and consistently high quality. The system ensures continuous production without downtime and reduces the risk of human error – leading to significantly improved productivity.

Benefits of the One-Man-Operator Concept:

Optimized Conformal Coating: Our Complete Solution for Your Production

Your electronics manufacturing deserves the best combination of efficiency, precision and quality. Our complete conformal coating solutions provide you with a fully integrated production line that leverages state-of-the-art technologies to ensure maximum process reliability and product quality.

Discover more about our complete conformal coating solutions and let our team provide you with an individual consultation to find the ideal line solution for your production.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: