Reflow Ovens for Reliable and Precise SMT Soldering

Reflow Ovens for Reliable and Precise SMT Soldering

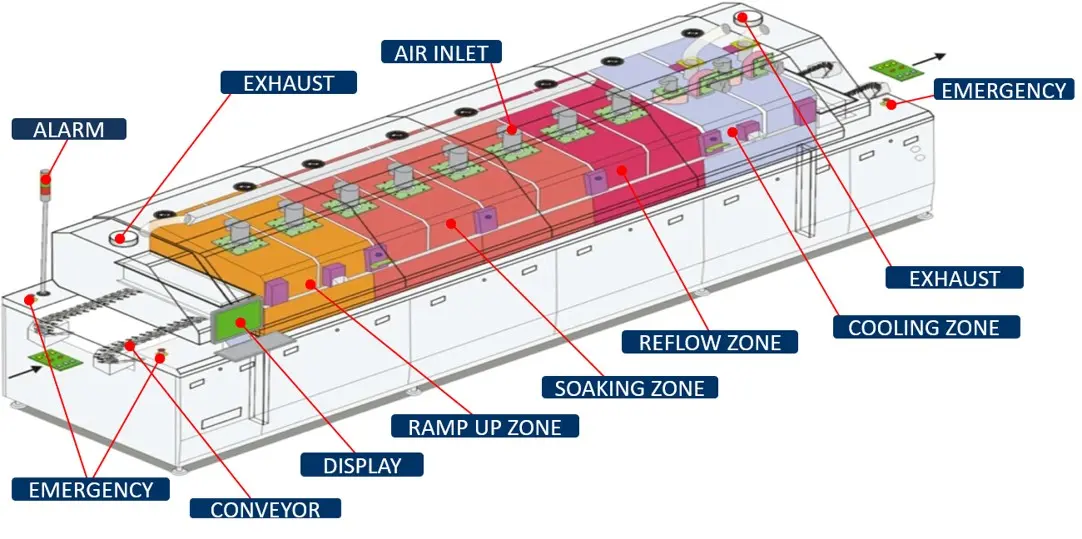

The highest soldering quality begins with the right equipment. Our reflow ovens offer an excellent price-performance ratio with outstanding heat transfer and automated process control. Each soldering oven is Industry 4.0 ready, supports complete traceability, and can optionally operate with nitrogen by connecting to an external N2 generator. Various sizes and zone configurations provide maximum flexibility for every SMT production line.

Discover the best solution now and future-proof your SMT line!

Our Reflow Ovens at a Glance:

Our Reflow Ovens at a Glance:

AR Series Soldering Oven

AR Series Soldering Oven

The AR Series reflow ovens address the growing demand for higher quality, greater process reliability, and increased efficiency in SMT soldering. With up to 12 heating zones and 3 cooling zones, optional nitrogen operation, and single- or dual-lane configuration, the model meets the highest standards of quality, stability, and flexibility.

Key Benefits:

RS-eCO Series Soldering Oven

RS-eCO Series Soldering Oven

The RS-eCO Series reflow soldering ovens stand for reliable, precise, and automated soldering in modern SMT manufacturing. With 6 to 12 heating zones, 1 to 2 cooling zones, and optional nitrogen operation, this model is perfectly suited for any SMT line. User-friendly operation and efficient heat transfer minimize soldering defects and ensure stable processes, making it ideal for modern electronics production.

Key Benefits:

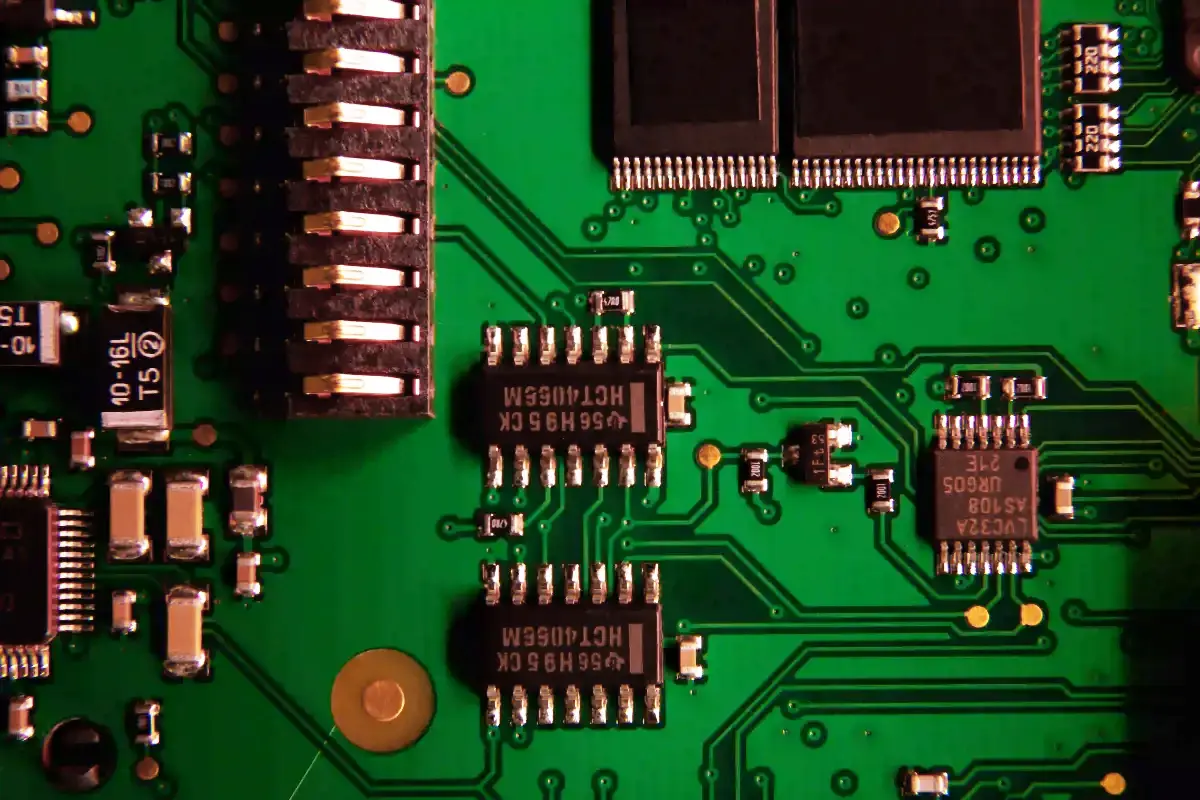

Reliable SMT Soldering: How Our Reflow Ovens Prevent Typical Defects

Reliable SMT Soldering: How Our Reflow Ovens Prevent Typical Defects

Designed by Freepik

Designed by Freepik

Your SMT Production in Focus: Our Turnkey Solutions

Your SMT production deserves the optimal combination of efficiency, precision, and quality. Our turnkey SMT lines provide fully integrated solutions with perfectly synchronized machines and cutting-edge technologies to ensure maximum performance and process reliability.

Discover more about our complete SMT line solutions and get expert advice from our team to find the perfect setup for your production needs.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: