The JUKI LX-8 is a next-generation SMT pick and place machine engineered to push the limits of speed, precision, and flexibility in modern electronics manufacturing. With up to 160 feeder slots, depending on the chosen placement head configuration. This machine delivers exceptional capacity while keeping its footprint compact. This smart design streamlines production setup and minimizes changeover times, allowing you to pre-load the next feeders in advance for uninterrupted operation.

A fully configurable dual-head system lets you equip the machine with two high-speed P20S heads, two flexible TAKUMI heads, or a combination of both. Whether you’re running high-mix or large-scale production, the unit maintains top performance, reaching placement speeds of up to 105,000 CPH with highest accuracy. Engineered for manufacturers who demand the best, the placement machine combines raw performance with unmatched adaptability – the perfect solution for today’s SMT production lines.

Technical Highlights of the SMT Pick and Place Machine:

Technical Highlights

of the SMT Pick and

Place Machine

of the SMT Pick and

Place Machine

Key Functions of the LX-8 SMT Placement Machine:

Key Functions of the

LX-8 SMT Placement Machine:

LX-8 SMT Placement Machine:

Verification Camera System

The unit ensures precise optical alignment of components using a VCS camera system that detects shapes, leads, and solder balls – even on complex components like QFPs and BGAs. This enables in-line inspection for defects such as bent leads or missing solder balls.

The 360° recognition capability compensates for unstable or misaligned components by automatically adjusting the placement angle. A multi-colour lighting system (red, green, blue) dynamically adapts to the material and geometry of each component, improving contour recognition and ensuring stable,

high-precision placement.

Verification Camera System

The unit ensures precise optical alignment of components using a VCS camera system that detects shapes, leads, and solder balls – even on complex components like QFPs and BGAs. This enables in-line inspection for defects such as bent leads or missing solder balls.

The 360° recognition capability compensates for unstable or misaligned components by automatically adjusting the placement angle.

A multi-colour lighting system (red, green, blue) dynamically adapts to the material and geometry of each component, improving contour recognition and ensuring stable, high-precision placement.

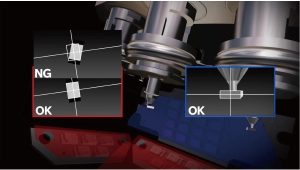

Сoplanarity model

An integrated coplanarity module detects planarity defects such as lifted leads on ICs or deformed solder balls on BGAs. Faulty components are identified before placement and excluded from the process, enhancing overall production reliability.

Laser Geometry Recognition with the TAKUMI Head

JUKI’s laser-based component recognition system identifies the shape, centre position, and rotation angle of components in real time as they move towards the placement position. This precise geometric analysis enables stable placement across a wide component range – from 03015 chips to QFPs up to 50 mm.

Operating independently of shape, colour or surface reflectivity the system ensures high recognition reliability for all component types. Misplaced parts, including defects such as tombstoning – are automatically detected for rework or rejection. This enhances overall process security and enables fast integration of new components through automatic data generation.

Laser Geometry Recognition with

the TAKUMI Head

the TAKUMI Head

JUKI’s laser-based component recognition system identifies the shape, centre position, and rotation angle of components in real time as they move towards the placement position. This precise geometric analysis enables stable placement across a wide component range – from 03015 chips to QFPs up to 50 mm.

Operating independently of shape, colour or surface reflectivity the system ensures high recognition reliability for all component types. Misplaced parts, including defects such as tombstoning – are automatically detected for rework or rejection. This enhances overall process security and enables fast integration of new components through automatic data generation.

High-Resolution Inspection System of the P20S Head

The innovative P20S head is equipped with a powerful vision system that enables precise real-time inspection and centering. With integrated bottom-view and side-view cameras, the system detects even the smallest deviations – such as incorrect orientations or missing components, before placement occurs. Especially for ultra-small components like 0201 chips (0.2 mm × 0.1 mm) or fine-pitch BGA packages, the advanced coaxial lighting technology ensures sharp imaging and highly reliable recognition. This guarantees consistently high placement quality, even for complex PCB layouts.

High-Resolution Inspection System of the P20S Head

The innovative P20S head is equipped with a powerful vision system that enables precise real-time inspection and centering. With integrated bottom-view and side-view cameras, the system detects even the smallest deviations – such as incorrect orientations or missing components, before placement occurs. Especially for ultra-small components like 0201 chips (0.2 mm × 0.1 mm) or

fine-pitch BGA packages, the advanced coaxial lighting technology ensures sharp imaging and highly reliable recognition. This guarantees consistently high placement quality, even for complex PCB layouts.

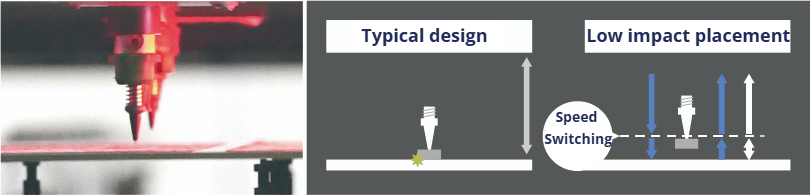

Low impact placement for flexible circuits

The Low Impact function enables fast switching and precise control of the nozzle’s downward and upward speed during placement. This significantly reduces mechanical stress on components and circuit boards. Especially in sensitive assemblies and flexible PCBs, the precise and gentle placement process improves reliability, reduces mechanical strain, and lowers the defect rate. As a result, this SMD pick and place machine ensures consistently high quality while maintaining maximum production efficiency.

Low impact placement for flexible circuits

The Low Impact function enables fast switching and precise control of the nozzle’s downward and upward speed during placement. This significantly reduces mechanical stress on components and circuit boards. Especially in sensitive assemblies and flexible PCBs, the precise and gentle placement process improves reliability, reduces mechanical strain, and lowers the defect rate. As a result, this SMD pick and place machine ensures consistently high quality while maintaining maximum production efficiency.

Your Benefits with the LX-8 SMT Placement Machine:

Your Benefits with the

LX-8 SMT Placement Machine:

LX-8 SMT Placement Machine:

Your SMT Production in Focus: Our Turnkey Solutions

Your SMT production deserves the optimal combination of efficiency, precision, and quality. Our turnkey SMT lines provide fully integrated solutions with perfectly synchronized machines and cutting-edge technologies to ensure maximum performance and process reliability.

Discover more about our complete SMT line solutions and get expert advice from our team to find the perfect setup for your production needs.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: