Stencil Printer for Precise and Reliable Solder Paste Printing in SMT Assembly

Stencil Printer for Precise and Reliable Solder Paste Printing in SMT Assembly

Approximately 70% of all defects in SMT production originate from the stencil printing process. Our stencil printers are engineered to secure this critical step: precise and fully automated, Industry 4.0 ready, equipped with SPI closed-loop systems, and flexibly configurable. Whether for large PCBs with the

P-Primo, ultra-short cycle times with the G-Tera, the highly flexible GL-Star, or the budget-friendly model G-Star – we provide the right solution for every production line.

Discover now: SMT printers tailored to every requirement in your SMT assembly line!

Our Stencil Printers at a Glance:

SMT Screen Printer G-Tera

SMT Screen Printer

G-Tera

G-Tera

The G-Tera solder paste printer is engineered for maximum precision and speed, making it the perfect solution for the increasing demands of modern SMT lines. It combines all the features of the GL-Star, including digital CCD camera and vacuum stencil locking, with advanced automation such as a linear-motor-driven independent cleaning system and

AGV-supported stencil change. Delivering stable, high-speed solder paste printing, this SMT screen printer sets new benchmarks in efficiency and process reliability – ideal for high-output lines with a strong focus on Industry 4.0.

Key Advantages:

SMT Screen Printer GL-Star

SMT Screen Printer

GL-Star

GL-Star

The GL-Star is a highly flexible, fully automatic stencil printer engineered for the demands of modern SMT lines. Equipped with advanced functions such as automatic stencil alignment, SPI closed-loop connection, precision PCB clamping, and automatic paste dispensing, this model increases process reliability and efficiency in your SMT production. An ideal choice for manufacturers prioritizing quality, reliability, and long-term automation security.

Key Advantages:

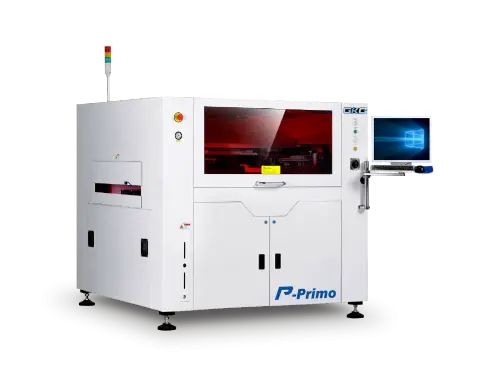

The P-Primo automatic stencil printer is a powerful solder paste printing system designed for extra-large PCBs in SMT production. With integrated 2D paste inspection and automatic PCB thickness adjustment, this model delivers top precision and flexibility – ideal for large, complex assemblies in “XL format”.

Key Advantages:

SMT Screen Printer G-Star

SMT Screen Printer

G-Star

G-Star

The G-Star SMT printer is a high-precision and cost-effective solution for modern SMT production. With an SPI closed-loop system, automatic solder paste dispensing, and short cycle times, this solder paste printer guarantees consistently high print quality while minimizing operator workload. Industry 4.0 compatibility and precise solder paste deposition make the G-Star the ideal entry-level model for efficient and reliable SMT assembly.

Key Advantages:

Your SMT Production in Focus: Our Turnkey Solutions

Your SMT production deserves the optimal combination of efficiency, precision, and quality. Our turnkey SMT lines provide fully integrated solutions with perfectly synchronized machines and cutting-edge technologies to ensure maximum performance and process reliability.

Discover more about our complete SMT line solutions and get expert advice from our team to find the perfect setup for your production needs.

Did You Know? We also have a dedicated webshop where you can find in-depth information, complete technical specifications

and a wide range of additional equipment for your production line. Get expert advice or place your order quickly and securely.

If you don’t have access yet, you can register for free right here: